MLC-V235 Continuous Casting Mold Level Control System

Oct 24th, 2024 at 02:42 Services New York City 9 views Reference: 4055Location: New York City

Price: Contact us

Overview

The automatic control for the molten steel level of the mold is one of the key technologies of continuous casting production. It is very important to reduce the labor intensity of workers, improve production efficiency, improve the quality and output of casting billet, reduce overflow and breakout of steel and improve the management level of steelmaking and continuous casting.

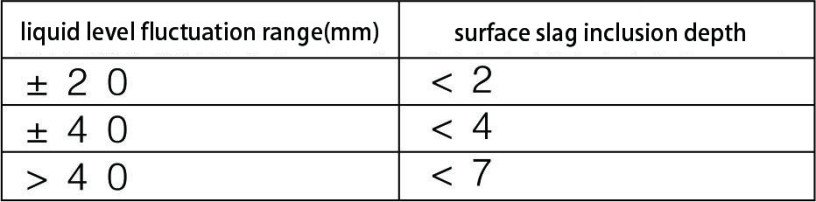

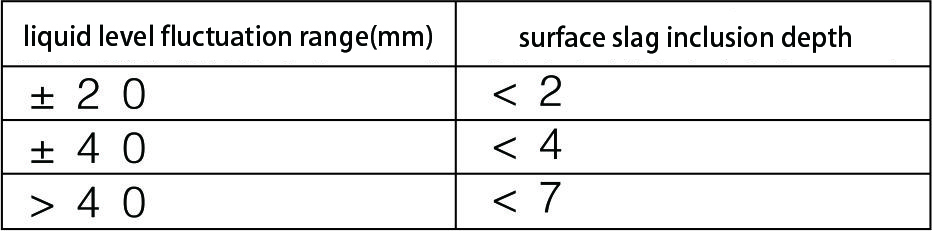

The molten steel is poured into the mold. In order to prevent overflow, the molten steel level must be kept stable. Otherwise, during the casting process, if the level will fluctuate too much, and slag will be involved, forming surface slag inclusion on the surface of the casting billet, affecting the quality of the billet. The test points out that the relationship between the level fluctuation and the depth of casting billet surface slag inclusion is as follows:

The experience has shown that surface slag inclusions can be eliminated when the level fluctuation is within ±10mm. At the same time, if the level fluctuation is more than 10mm, the rate of longitudinal cracks on the casting billet surface is 30%. It means that the level fluctuation directly affects the surface quality of the casting billet.

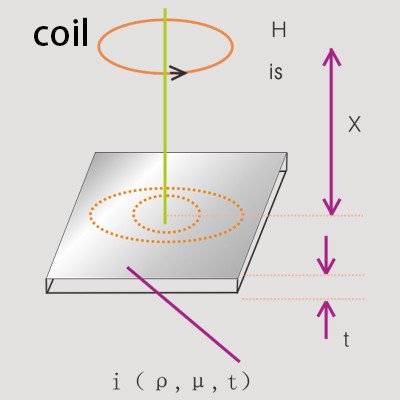

The principle of the system

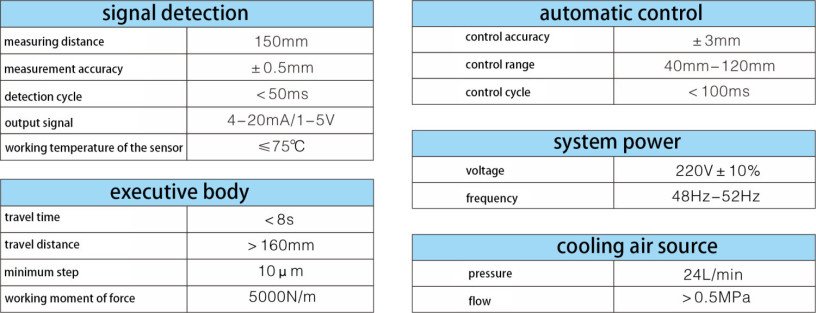

The eddy current type molten steel level gauge is the key to the system. The system operates reliably and has excellent performance: high temperature resistance, strong anti-interference ability, fast dynamic response (lag time <0.10s), high detection accuracy (<±05mm), and large measurement range (0-150mm). The selected electromagnetic field frequency ensures that the level detection probe only detects the level change of the mold and does not detect the mold flux or steel slag layer. The system has the advantages of simple operation and no radiation protection problems. The system is insensitive to argon blowing, and its sensors can be mounted on the tundish car or on the platform.

The sensor is cooled by compressed air during use.

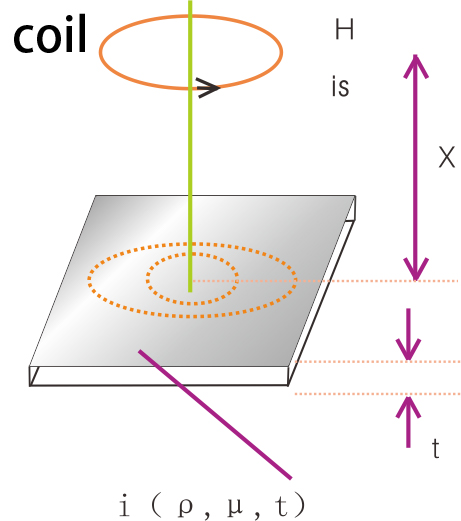

The principle is shown in the figure

A high-frequency exciting winding is installed above the molten steel surface of the mold. The high-frequency magnetic field generated by the high-frequency exciting winding induces eddy currents on the molten steel surface to form a magnetic field. The magnetic field generated by the induced eddy current is in the opposite direction to the magnetic field generated by the high-frequency exciting winding, which changes the impedance of the high-frequency exciting winding. Under the condition that the winding material and structure, steel grade, temperature remain unchanged, the coil impedance change only has a single-value function relationship with the height of the molten steel level. As long as the impedance change of the high-frequency winding is detected, the change of the molten steel level in the mold can be converted.

The components of the system

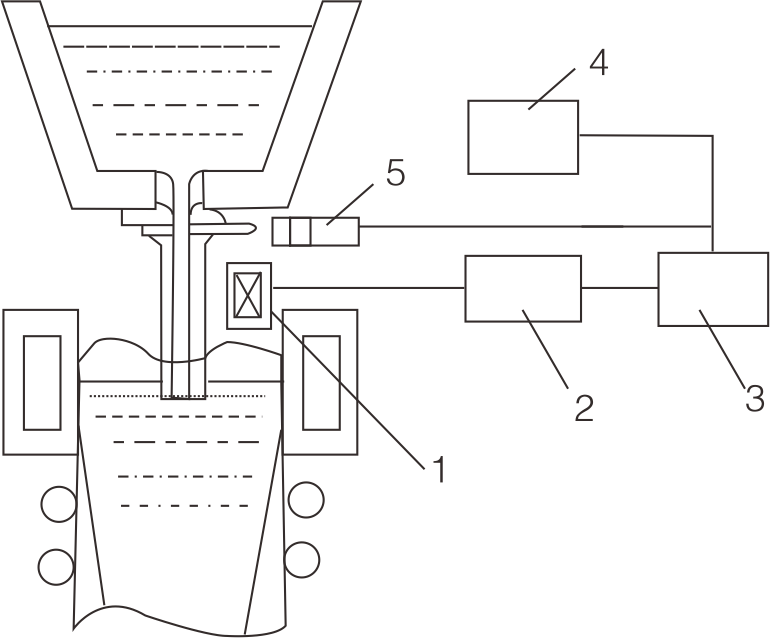

Continuous casting mold level automatic control system is composed of eddy current tyoe molten steel level gauge, controller and digital actuator for adjusting the opening of tundish stopper.

The detection end of the mold level automatic control system is ① eddy current displacement sensor, which uses the eddy current mutual inductance effect between the energized coil and the metal conductor to detect the distance. The effective signal of the eddy current sensor is amplified and linearized by the circuit of ② mold level gauge, which converts the 0-150mm change in the molten steel level of the mold into a standard signal of 4-20mA.DC, and then transmits it to the ③ control computer to complete data processing and system control functions. We can also control the actuator manually and automatically through the ④on-site operation display control panel, and the opening of the stopper is controlled by the ⑤ actuator to realize the automatic control of the molten steel level.

1 Eddy current sensor;

2 mold level gauge;

3 control computer;

4 On-site operation display control panel;

5 digital actuator;

The control principle of the system

The system can be set to four control modes: automatic, semi-automatic, manual and motor clutch. The automatic mode is the closed-loop control system of the molten steel level, and control the opening of the stopper by the digital actuator; the semi-automatic mode uses opening degree setter and digital actuator to set the opening of the stopper manually; the manual mode is to open and close the button directly to control the opening of the stopper; the motor clutch mode is quickly changed from any of the above control methods to manual stopper operation.

The functions of the system also include: display and record of molten steel level, nozzle opening and casting speed; setting of molten steel level and nozzle opening; alarm of molten steel level at limit value etc.

In addition to taking the detection of molten steel level as the main feedback signal of the control system, the control system also considers various interference factors that have an impact on the level control. These interference factors include:

1. The influence of the change of the flow characteristics on the control system after the melt loss of the stopper

2. The influence of the weight change of molten steel in the tundish on the control system

3. The influence of the change of the casting speed of the continuous casting machine on the control system

4. The influence of the mold width change (the mold width is adjustable) on the control system

5. The influence of the vibration frequency and amplitude of the mold on the molten steel level gauge